Once you set the initial ambient conditions it is vital to measure them frequently and monitor the results in real time.

Avoiding high temperatures, reducing changes in humidity levels and cutting long exposure times are critical. Therefore, maintaining cold chain integrity is crucial from production to transportation and consumption.

Perishable goods (such as dairy products, meat, fish and frozen food) and sensitive products (like vaccines and medicine) deteriorate quickly if not stored under prescribed conditions.

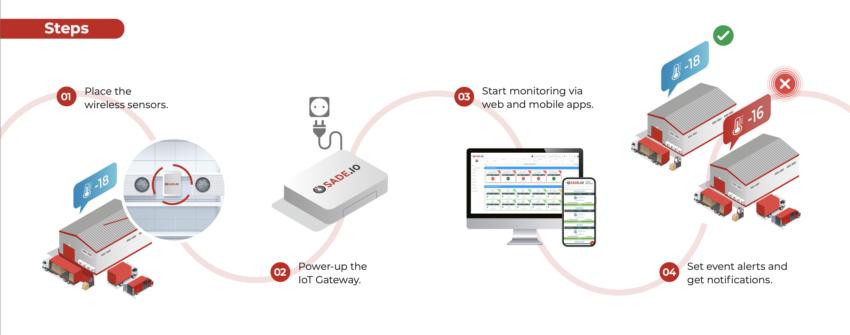

SADELABS’ end-to-end, integrated, advanced remote monitoring solution will not only prevent the deterioration of perishable goods but also help increase health and quality standards, boosting both savings and consumer trust of manufacturers and retail stores.

Advantages of End-to-End IoT-Based Advanced Remote Monitoring Applications

Areas of Use

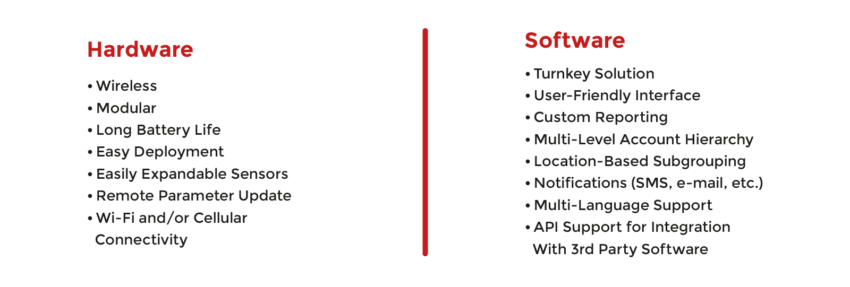

With 60+ years of accumulated experience, SADELABS has specialised for 15 years in innovative hardware and software solutions for end-to-end, turn-key industrial applications in the field of the Internet of Things. In line with our vision of producing innovative technology solutions on a global scale, we are growing together with our expert team and global partner ecosystem.