A Tale of IoT Transformation with SADE.IO: Transforming Quality Control in Appliance Production through SADE.IO’s Remote Temperature Monitoring Solution for IoT

We take great pride in presenting a practical instance of our cold chain solution based on IoT, developed in partnership with a leading manufacturer of refrigerators and freezers. This collaboration serves as a prime example of how advanced technology can elevate quality control procedures and safeguard product authenticity.

What We Have Achieved:

- Elevated Quality Assurance: Continuous temperature monitoring guaranteed conformity of every appliance to quality benchmarks.

- Streamlined Operations: The automated gathering and analysis of data optimized the quality control workflow, minimizing the need for manual involvement.

- Instant Decision Facilitation: Operators promptly received appliance status updates, enabling swift corrective measures when needed.

- Sustainable Sensor Use: Sensors were recoverable after each cycle, permitting their utilization in subsequent production phases.

- Data Storage: Captured temperature data were stored and retrieved for future evaluations, fostering ongoing process enhancements.

The Situation:

A distinguished manufacturer of white goods, our transformer encountered the task of upholding exacting quality control measures for their cooling appliances. Given the requirement to oversee internal temperatures throughout production and guarantee alignment with established criteria, a dependable and effective solution became imperative.

Solution:

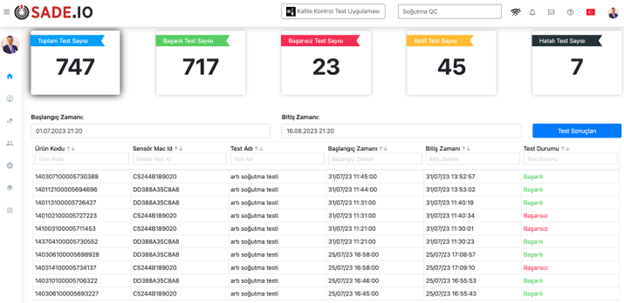

Utilizing our IoT-based remote temperature monitoring solution, we revolutionized quality control. Wireless sensors, linked to unit serial numbers, were placed in refrigerators and freezers during production. These sensors continuously tracked internal temperatures, sending data to the SADE.IO IoT platform via an LTE gateway.

How does it work?

- Wireless sensors connected to unit serial numbers.

- Sensors monitor temperatures during production.

- Data sent to the IoT platform via LTE gateway.

- Platform processes data, determining compliance.

- ‘OK’ or ‘Not-OK’ result shown on tablet interface.

This use-case demonstrates how our IoT-based remote temperature monitoring solution can empower manufacturers to uphold stringent quality control measures. By embracing technology, businesses can achieve superior product quality, operational efficiency, and customer satisfaction.

To learn more about our innovative solution and how it can transform your processes, contact us at global@sade.io