The ‘‘cold chain’’ is a term that refers to the series of actions and equipment that are used to keep a product within a specified low-temperature range, from the point of production to the point of consumption. The cold chain is essential for preserving the quality and safety of many products, such as food, medicine, chemicals, and vaccines. A cold chain can also help reduce waste and losses by extending the shelf life of perishable products.

Cold chain monitoring is the process of tracking and measuring temperature-related conditions throughout all stages of a product. Cold chain monitoring can help ensure that the product maintains its desired temperature range throughout its journey, and that any deviations in temperature and humidity levels or breaches are detected and corrected as soon as possible. Cold chain monitoring can also provide data and insights for improving the efficiency and effectiveness of the cold chain.

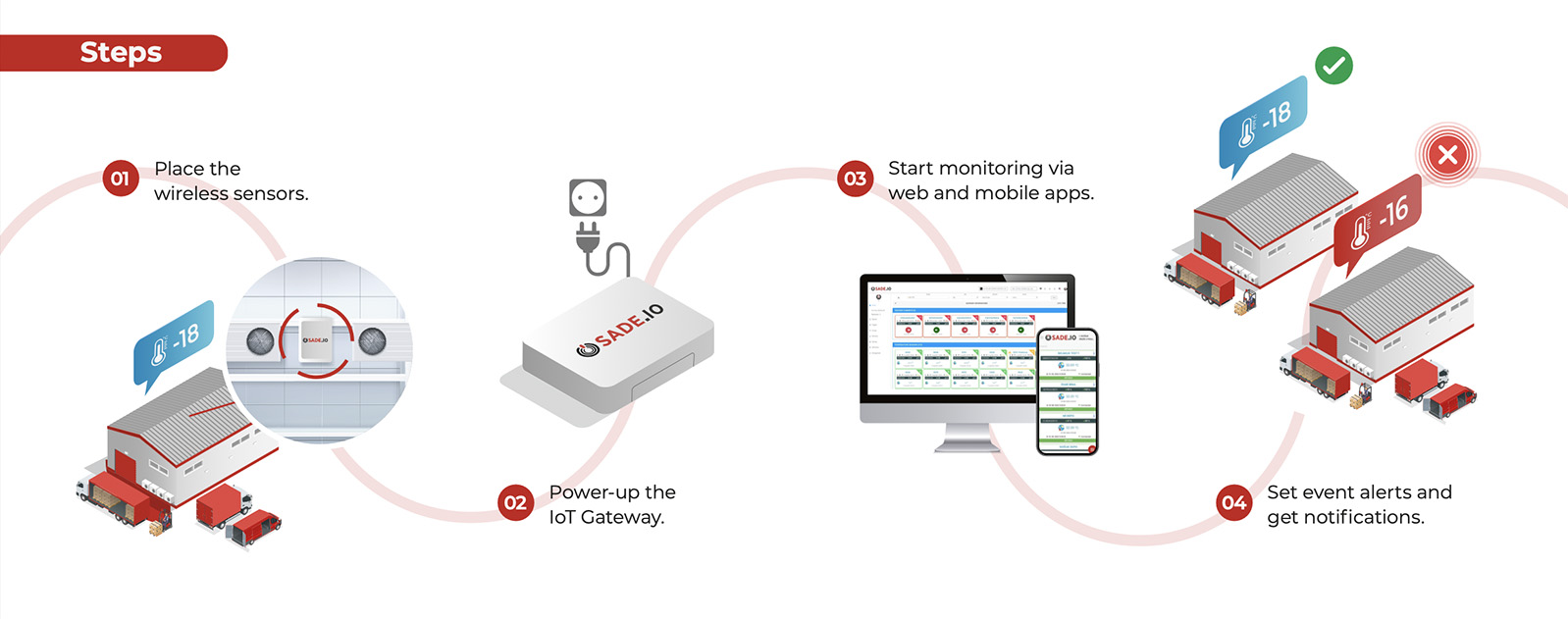

Cold chain monitoring can be achieved using various methods and technologies, such as sensors, loggers, indicators, software, and cloud-based platforms. These tools can collect, store, transmit, analyse, and visualise environmental data from different stages of the cold chain.

Some examples of cold chain monitoring solutions are as follows:

– Smart labels: These are stickers or tags that change colour or display information based on the temperature exposure of a product. They can provide a simple, low-cost way to indicate if a product has been exposed to unacceptable temperatures.

– Data loggers: These devices record temperature data at regular intervals and store them in internal memory or an external storage medium. This can provide a detailed history of the temperature conditions of a product along the cold chain.

– Wireless sensors: These devices measure temperature data and transmit them wirelessly to a receiver or a network. They can provide real-time information and alerts on the temperature status of a product along the cold chain.

– Cloud platforms: These are online services that collect, store, process, and display temperature data from various sources. They can access temperature data from anywhere and anytime, as well as advanced analytics and reporting capabilities.

Cold chain and cold chain monitoring are essential aspects of supply chain management for many industries and sectors. Maintaining perishable goods within a specified low-temperature range from production to consumption and monitoring remotely helps ensure quality, safety, efficacy, and value and resolves any issue that may compromise.